Water Main Breaks & National Trends: A Broader Context

By Greg Baird

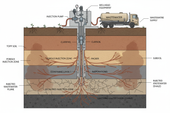

WaterOne’s journey toward resilient infrastructure through PVC adoption, discussed in Water Finance & Management’s Q4 cover story, is part of a larger national narrative. The 2025 ASCE Infrastructure Report Card assigns a C grade to the nation’s drinking water systems — unchanged from 2021 — highlighting persistent challenges that utilities across the country face. The U.S. drinking water infrastructure includes over 2 million miles of underground pipes, many of which were installed in the 19th and mid-20th centuries. These systems are aging rapidly, with 20% of installed water mains — approximately 450,000 miles — having exceeded their useful life. Despite this, many remain in service due to inadequate funding for replacement.

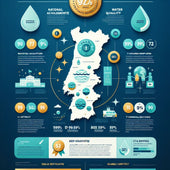

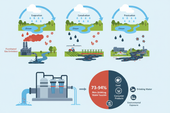

The Environmental Protection Agency (EPA) estimates that $625 billion is needed over the next 20 years to bring the nation’s drinking water infrastructure to a state of good repair. Of this, $421 billion (67%) is required for distribution and transmission systems alone. While federal programs like the Infrastructure Investment and Jobs Act (IIJA) have injected capital into the sector, funding shortfalls persist — especially in state revolving funds and smaller, disadvantaged communities. Aging infrastructure contributes to significant water loss.

The ASCE report estimates that 33.3 trillion gallons of water are lost annually, resulting in $187 billion in lost revenue. Additionally, monthly household water bills have increased by 64% between 2012 and 2023, driven by inflation and rising labor costs. Yet, only 20% of utilities report being fully able to cover the cost of drinking water services.

Compounding these issues are emerging contaminants like PFAS, cybersecurity threats, and workforce shortages. The EPA reports that 9.2 million lead service lines remain in operation, and PFAS contamination affects more than 130 million people, with an estimated $2.7 to $3.5 billion annually needed for treatment systems. Meanwhile, one-third of the water workforce is eligible to retire within the decade, and only 10% of workers are under age 24.

Despite these challenges, there are signs of progress. Water main breaks have decreased by 20% annually since 2018, largely due to the replacement of high-failure materials like cast iron and asbestos cement with ductile iron and PVC. WaterOne’s proactive shift to PVC aligns with this national trend and demonstrates how data-driven decisions can improve system reliability, reduce costs, and enhance public health outcomes.

Resilient Infrastructure through Informed Decisions: WaterOne’s Pipe Journey

WaterOne and the National PVC Trend

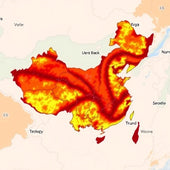

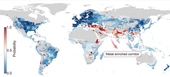

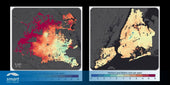

WaterOne’s transition from ductile iron to PVC pipe mirrors a broader national trend toward modern, corrosion-resistant materials. As shown in the regional maps from the 2012, 2018, and 2023 USU studies, utilities across the U.S. and Canada are increasingly adopting PVC — especially in Regions 3, 4, 5, 7, and 9. These areas now report PVC as the predominant pipe material, replacing legacy materials like cast iron and asbestos cement.

WaterOne’s data-driven approach — beginning in 2008 and reaffirmed in 2020 — demonstrates the same motivations driving national change: lower break rates, corrosion immunity, ease of installation, and long-term cost savings. The utility’s internal data showing PVC C900 with break rates as low as 3.1 per 100 miles per year aligns with the national average of 2.9, reinforcing PVC’s reliability.

This alignment between WaterOne’s local experience and national trends underscores the value of PVC as a resilient, sustainable infrastructure material. As utilities face aging systems and funding shortfalls, PVC offers a proven path forward.

COMMENTARY: Americans Deserve Accurate Information About PVC Pipe for Drinking Water

Safety and Sustainability of PVC Pipe

Beyond performance, PVC pipe offers significant safety and environmental benefits. Decades of research and real-world use confirm its safety for drinking water systems. PVC does not leach harmful chemicals, and its production process results in a chemically stable, non-toxic material. U.S.-made PVC pipe meets or exceeds safety standards set by the National Sanitation Foundation (NSF) and the American National Standards Institute (ANSI).

More than 10 million water-quality tests have confirmed non-detect levels of vinyl chloride monomer (VCM), the compound used in PVC production. The polymerization process ensures that VCM is chemically bound and cannot leach into water. PVC also has a lower carbon footprint than other pipe materials. Its smooth interior walls reduce pumping energy, and its long service life minimizes the need for replacement.

The industry has completed life cycle assessments and environmental product declarations in accordance with ISO standards, confirming PVC’s sustainability and safety.

Greg Baird, MPA, is a Principal Utility Financial Consultant with Black & Veatch. A former utility CFO, he specializes in long-term utility planning, infrastructure asset management and capital funding strategies for municipal utilities in the United States. He is a frequent contributor to Water Finance & Management.

The post Water Main Breaks & National Trends: A Broader Context appeared first on Water Finance & Management.