Saving water and emissions

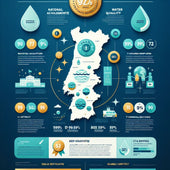

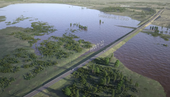

Water is a valuable resource, and this is especially true in times of increasing weather extremes, such as floods or periods of drought.

Like many other countries, Australia frequently experiences water scarcity. Non-revenue water (NRW), which accounts for between ten and 25 per cent of the water produced and lost before it reaches the customer, even contributes to this scarcity.

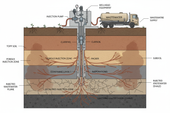

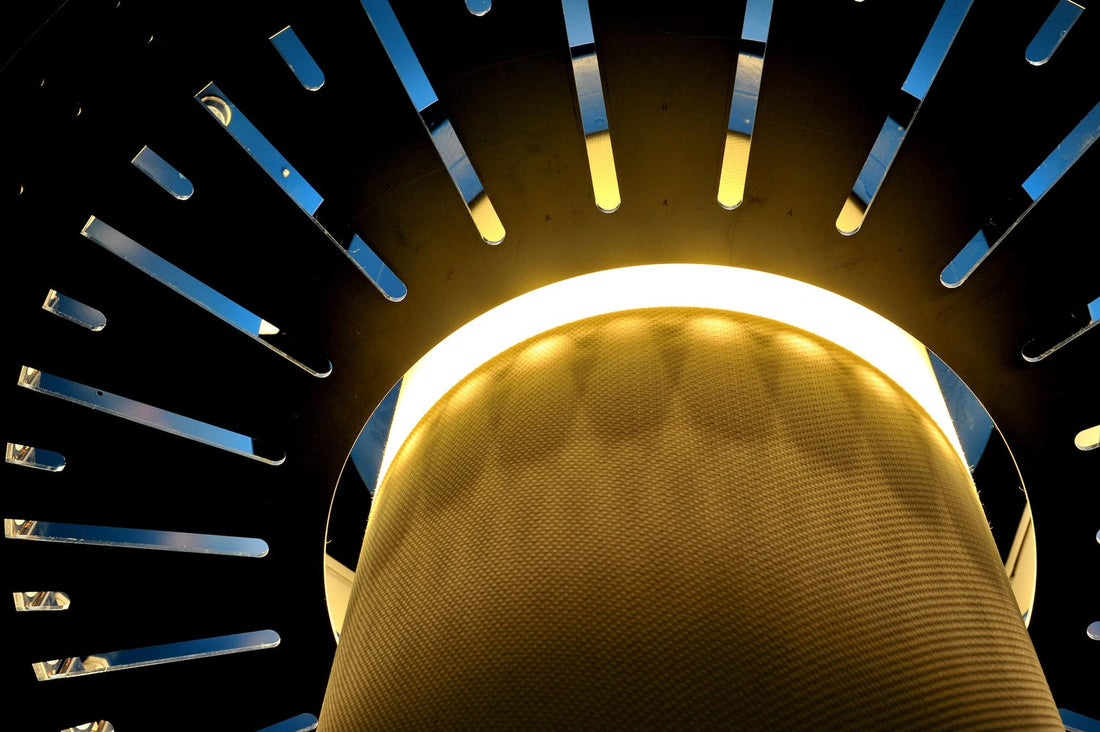

Using sustainable trenchless methods such as the Primus Line® technology to rehabilitate defective water mains can help reduce both water loss and emissions. In addition, the recently defined carbon footprint of the product makes it comparable to traditional lift-and-lay construction.

The advantages of trenchless rehabilitation methods with regard to greenhouse gas (GHG) emissions are meanwhile now well-known and proven.

Firstly, there are significantly fewer or even no traffic delays and diversions. Trenchless methods require less construction machinery and smaller construction pits allow for faster installation than open trenching. Therefore, the amount of excavated material that needs to be disposed of is reduced. Transporting construction materials to the respective site by truck is minimised, as is fuel consumption and the overall need for construction materials such as asphalt concrete, stones and backfill material.

All of this results in considerably reduced noise and fine dust emissions. Depending on the circumstances of the project, using trenchless technologies can reduce GHG emissions by up to 90 per cent. Not to mention the savings in construction, social and environmental costs.

Despite all these well-known benefits, it has however been difficult to compare the GHG emissions of a defined relining product with those of other commonly used traditional lift-and-lay materials.

In order to make the climate impact of their products transparent and comprehensible, Rädlinger Primus Line is one of the first liner manufacturers to calculate the CO2 footprint for each of their liners for water, gas and oil applications, per running metre. This emissions assessment for each product in the form of an Environmental Product Declaration (EPD) enables CO2 emissions to be determined quickly and easily on a project-specific basis, and to be compared to other (open trench) materials. This information can be relevant in bidding processes.

Rädlinger Primus Line’s carbon footprint calculations are based on a cradle-to-gate approach, covering the products’ entire lifecycle up to the company’s gate in the supply chain, including the sourcing of raw materials, production and transport up to that point.

Calculating the carbon footprint of their products is part of Rädlinger Primus Line’s sustainability strategy. They have their greenhouse gas inventory determined annually by an independent, external service provider whose testers and validators are certified according to ISO 14064-3. Rädlinger Primus Line’s GHG inventory for 2023 amounts to 6,427 tCO2e, equivalent to the emissions of 8.5 flights from Munich to New York and back, or to around 1816 EU households. This represents less than 0.001 per cent of all EU households.

In addition, Rädlinger Primus Line’s internal energy team at the headquarters in Germany is continuously working to improve the energy efficiency. Measures in this respect include the use of renewable energy through photovoltaics on the company buildings, heat recovery and heat pump technology for in-house use at the Primus Line logistics facility and the ongoing development of an electric fleet.

If you are interested in a green relining solution, sustainability report as well as EPDs are available on request: www.primusline.com/en-au/

The post Saving water and emissions appeared first on Utility Magazine.