From Surgery to Water Systems: How the Checklist Manifesto Transforms Utility Performance

When Dr. Atul Gawande introduced the surgical checklist to operating rooms worldwide, he demonstrated something profound: even the most skilled professionals benefit from systematic verification. His principles, outlined in "The Checklist Manifesto," translate remarkably well to water utility operations—another field where expertise meets complexity, where routine procedures carry high stakes, and where consistent execution determines public safety.

This translation matters because water utilities face a fundamental challenge: how do public sector operations achieve the consistency and reliability that markets demand? The answer lies not in replacing expertise with automation, but in using structured processes to elevate performance systematically.

The Technology Trap: Gawande's Critical Observation

One of Gawande's most striking observations cuts directly to a common organizational failure: entities invest heavily in the latest technology and expensive assets while systematically underinvesting in the unglamorous work of communication protocols and verification checklists. This pattern appears consistently across industries—hospitals purchase advanced imaging equipment but lack standardized handoff procedures; airlines acquire sophisticated aircraft but initially resisted basic pre-flight verification lists.

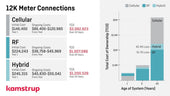

Water utilities follow this same pattern with remarkable precision. Agencies readily approve capital budgets for advanced SCADA systems, membrane treatment technology, or state-of-the-art pumping stations. These investments are visible, measurable, and politically attractive—they appear in ribbon-cutting ceremonies and annual reports.

Meanwhile, the fundamental operational protocols that determine whether this expensive technology actually delivers consistent performance receive minimal attention. Utilities may lack standardized shift handover procedures, resulting in critical information loss between operators. Emergency response protocols exist as binders on shelves rather than practiced routines. Water quality verification steps remain informal rather than systematized. Communication pathways between operations, maintenance, and management stay unclear until failures expose the gaps.

The economics reveal the disparity: a utility might spend $50 million on treatment plant upgrades while resisting investment in developing and implementing operational checklists—work that might cost $200,000 but would dramatically improve how effectively that $50 million in assets performs.

This misallocation isn't about malice or incompetence. It reflects predictable organizational incentives: hardware is tangible and its purchase represents clear action; process improvement is invisible and its benefits emerge gradually. Capital investments have constituencies—equipment vendors, construction firms, engineering consultants. Process systematization has no natural advocates beyond the frontline operators who experience its absence daily.

Yet Gawande's research demonstrates conclusively that the unglamorous work of systematic communication and verification often delivers performance improvements that expensive technology alone cannot achieve. The surgical checklist he studied cost almost nothing to implement but reduced complications by more than one-third. The benefit wasn't the checklist paper—it was the discipline of verification, the standardization of communication, and the creation of clear decision points.

For water utilities, this insight matters profoundly. The path to elevated performance doesn't require choosing between technology and processes—it requires recognizing that expensive assets deliver value only when operated through systematic protocols. A $10 million treatment system performs reliably when operators follow standardized startup procedures, verify water quality at critical control points, and communicate effectively across shifts. Without these processes, even sophisticated technology produces inconsistent results.

The Core Translation: Why Water Operations Mirror Aviation and Medicine

Gawande's research focused on environments where knowledge alone isn't sufficient—where the gap between knowing and doing creates risk. Water utilities share three critical characteristics with the medical and aviation sectors he studied:

• High-stakes outcomes where failures have serious public health and environmental consequences

• Complex multi-step processes requiring coordination across departments and shifts

• Mix of routine and emergency situations demanding both disciplined execution and adaptive response

Consider a water treatment plant during a weather event. Operators must monitor multiple parameters, adjust chemical dosing, manage reservoir levels, coordinate with distribution teams, and communicate with emergency services—all while maintaining regulatory compliance. Like a surgical team or flight crew, they're executing well-understood procedures under time pressure where any single oversight could cascade into system failure.

Four Principles for Systematic Performance Elevation

1. Managing Complexity Through Disciplined Standardization

Gawande's insight was that checklists don't replace expertise—they free experts to apply their knowledge where it matters most. In water operations, this means codifying routine procedures so operators can focus cognitive resources on judgment calls.

Practical applications:

• Water quality testing protocols with verification steps for each parameter

• Treatment plant startup and shutdown sequences preventing equipment damage and water quality excursions

• Chemical dosing verification procedures reducing both safety risks and treatment costs

• Preventive maintenance schedules ensuring equipment reliability without excessive downtime

The International Water Association's Performance Indicator System provides a framework for measuring how effectively these standardized processes translate into outcomes. Utilities that systematically implement operational checklists show measurably better performance on indicators like water quality compliance rates and unplanned outage frequency.

2. Communication and Coordination Across Boundaries

One of Gawande's most powerful findings was that the simple act of team members stating their names and roles before surgery dramatically reduced errors. The mechanism: explicit communication creates shared situational awareness and psychological permission to speak up when problems emerge.

Water utilities operate across similar organizational boundaries—between shifts, between treatment and distribution, between operations and maintenance, between field crews and control rooms. Each boundary is a potential point of information loss.

Checklist-driven coordination mechanisms:

• Shift handover protocols ensuring critical information transfers between operators

• Cross-departmental emergency response checklists defining roles and communication pathways

• Operator-to-supervisor escalation procedures with clear triggers and response timelines

• Inter-agency coordination protocols for binational water systems or regional emergencies

The practical impact shows in regulatory compliance rates. Utilities with structured communication protocols consistently achieve higher scores on regulatory audits because information flows reliably from field observations to management decisions to regulatory reporting.

3. Verification Over Trust: Building Systematic Reliability

Gawande found that even experienced surgeons make errors—not from lack of knowledge, but from inevitable human lapses in complex environments. The solution isn't questioning competence; it's building verification into routine practice.

In water operations, verification mechanisms create the reliability that defines the difference between adequate and excellent utility performance:

• Critical control point monitoring with automatic alerts when parameters drift outside acceptable ranges

• Dual verification for high-risk operations like chemical tank switching or system isolation

• Post-incident review checklists ensuring root cause analysis and corrective action implementation

• Regulatory compliance verification before submitting reports or certifications

This approach aligns with ISO 24516 standards for water utility asset management, which emphasize systematic verification as fundamental to service reliability. The standard recognizes that sustainable performance requires processes that catch errors before they become failures.

4. Empowering Frontline Judgment Within Clear Boundaries

Perhaps Gawande's most counterintuitive finding was that good checklists empower rather than constrain professionals. They establish clear decision points where expert judgment is required and create the conditions for that judgment to be applied effectively.

In water utilities, this translates to defining when operators have both the authority and obligation to make critical decisions:

• Authority to pause or modify operations when monitored parameters fall outside normal ranges

• Standardized escalation procedures that operators must follow when facing uncertain situations

• Clear protocols for emergency decision-making when normal communication channels are unavailable

• Documentation requirements that support learning rather than simply assigning blame

This balance between standardization and empowerment is what distinguishes high-performing utilities. Operators know both what they must do consistently and when they must apply judgment. The result is a system that's simultaneously reliable and adaptive.

Elevating Government Performance to Market Standards

The broader significance of applying checklist methodology to water operations connects to a fundamental question in public sector performance: how do government-operated systems achieve the consistency that competitive markets normally enforce?

As economist Raghuram Rajan argues in "The Third Pillar," effective governance requires institutions that can match market efficiency without market mechanisms. Water utilities—natural monopolies operating critical infrastructure—represent this challenge in concrete form.

The checklist approach provides a pathway: by systematizing operational excellence, utilities create internal mechanisms that produce the reliability markets would otherwise enforce through competition. This isn't about making government operations identical to private enterprise; it's about achieving comparable outcomes through different means.

Consider performance benchmarking data from the European Water Association. Utilities that have implemented systematic operational protocols—the checklist methodology in practice—show performance distributions nearly identical to their privately-operated counterparts on technical metrics like non-revenue water percentages, supply interruption frequencies, and water quality compliance rates. The difference isn't ownership structure; it's systematic approach to operational discipline.

Implementation: From Principle to Practice

Translating checklist principles into operational reality requires more than documenting procedures. Gawande emphasizes that effective checklists are brief, focused on critical steps, and tested in real conditions. For water utilities, this means:

Starting with high-impact, high-risk operations:

• Water quality testing and treatment verification

• Emergency response protocols

• Critical equipment startup and shutdown

Developing checklists collaboratively with frontline operators:

• Operators identify where current procedures create risk or inconsistency

• Draft checklists undergo field testing and refinement

• Regular review cycles incorporate operational learning

Measuring impact through performance indicators:

• Reduction in water quality excursions

• Decrease in unplanned equipment outages

• Improvement in regulatory compliance rates

• Enhanced emergency response times

The World Health Organization's Water Safety Plan methodology provides a structured framework for this implementation, recognizing that systematic operational protocols are fundamental to sustainable safe water supply.

The Path Forward: From Individual Excellence to Systematic Reliability

Gawande's fundamental insight—that modern complexity exceeds individual cognitive capacity regardless of expertise—applies directly to water utility operations. The question isn't whether operators are skilled or dedicated; it's whether the system they work within consistently supports excellent outcomes.

The checklist methodology offers water utilities a pathway to elevate performance systematically. By standardizing critical procedures, improving communication across organizational boundaries, building verification into routine operations, and empowering frontline judgment within clear frameworks, utilities can achieve the reliability that defines world-class performance.

This isn't about replacing human expertise with mechanical compliance. It's about creating the conditions where expertise can consistently produce excellent results—where government-operated systems achieve the performance that markets demand and communities deserve.

The translation from surgery to water systems proves remarkably direct: complex operations serving critical public needs require systematic approaches that free professionals to apply their judgment where it matters most. That's the enduring lesson of the Checklist Manifesto for water operations performance.